Tekleen Filters Increase Efficiency at Hoffer Plastics

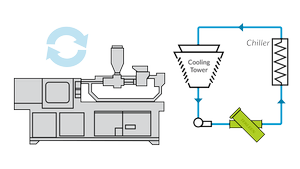

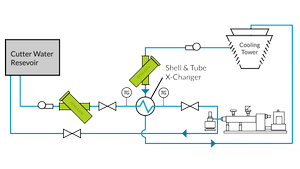

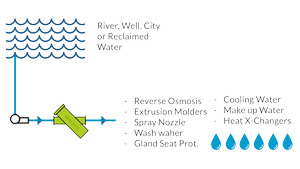

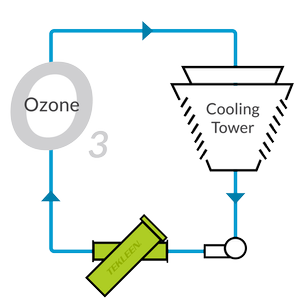

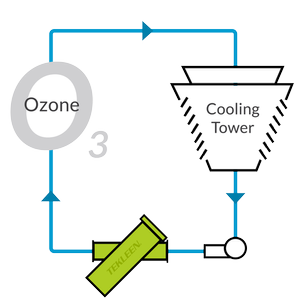

Tekleen Filters Increase Efficiency at Hoffer Plastics Hoffer Plastics Corporation in South Elgin, IL is comprised of a 365,000 square foot climate-controlled, self-powered facility. There are eight focused factory operations within the facility to serve the company’s primary markets –