Food Industry

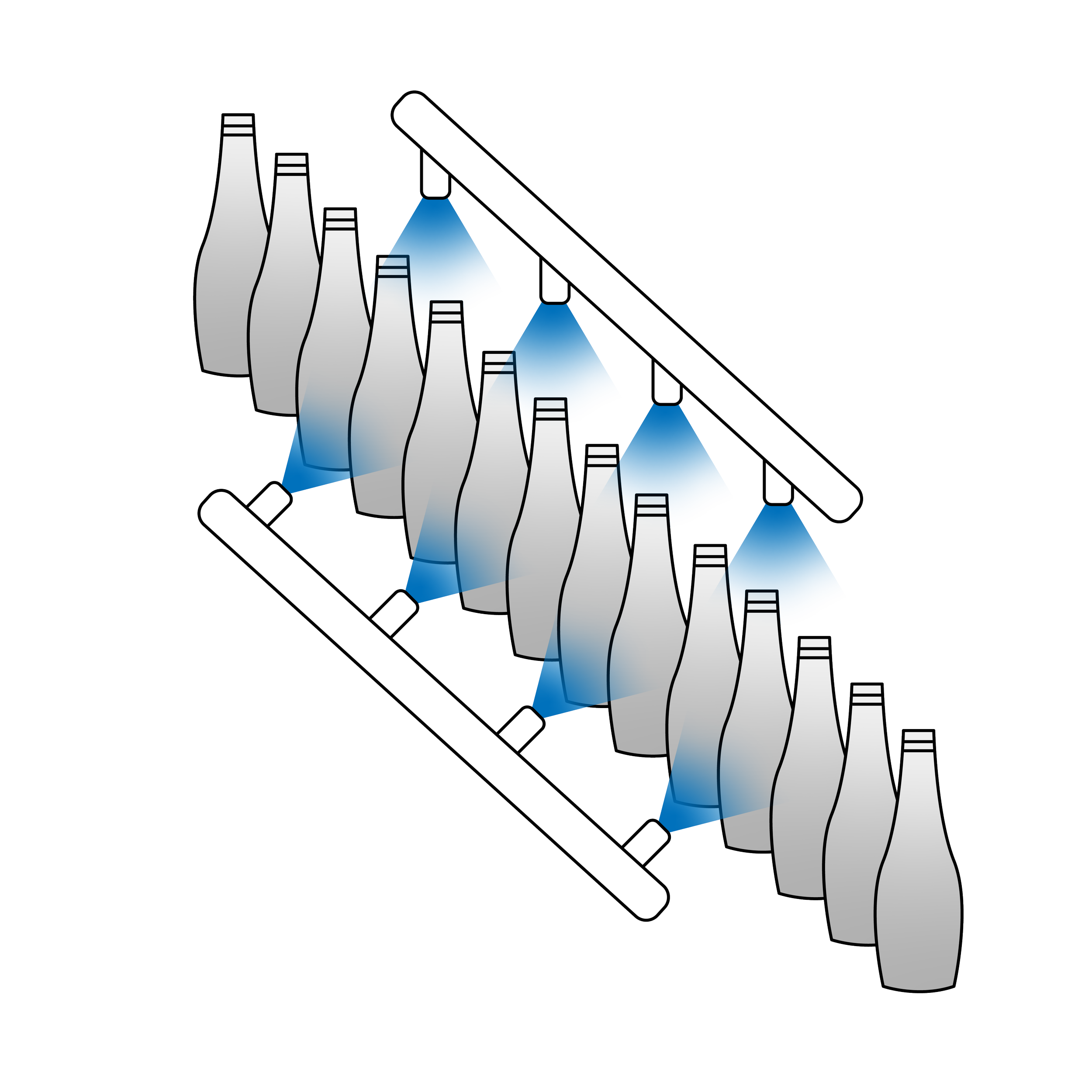

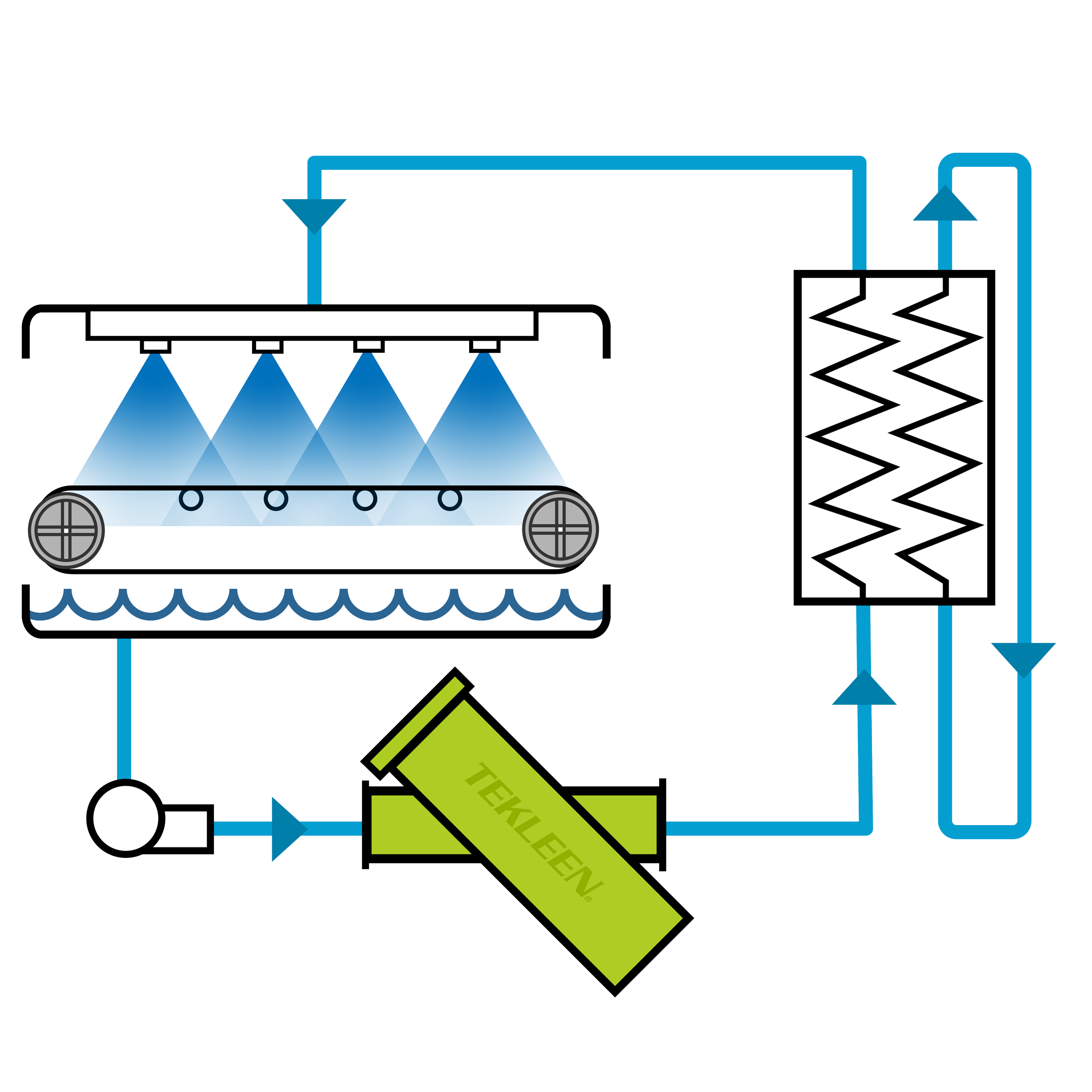

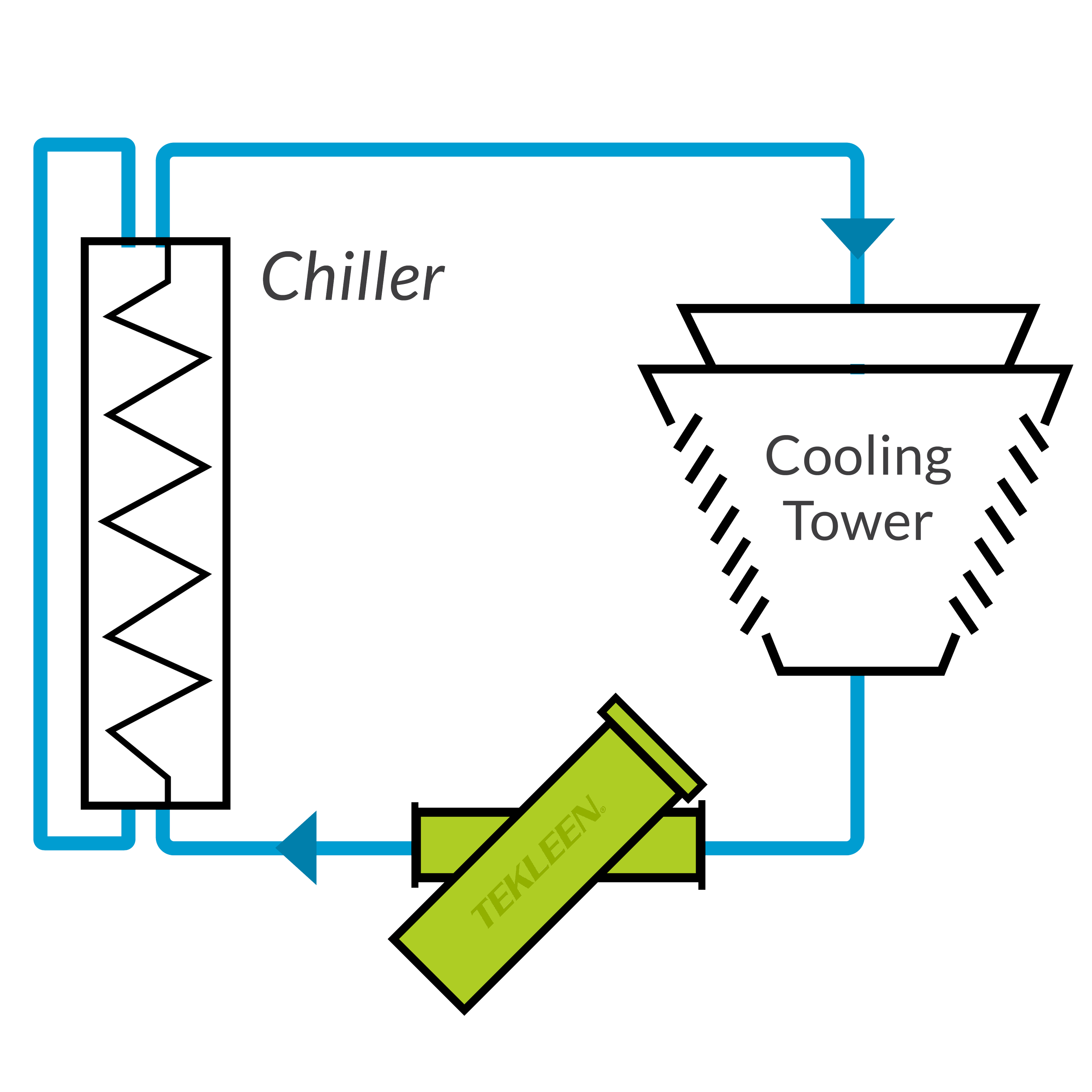

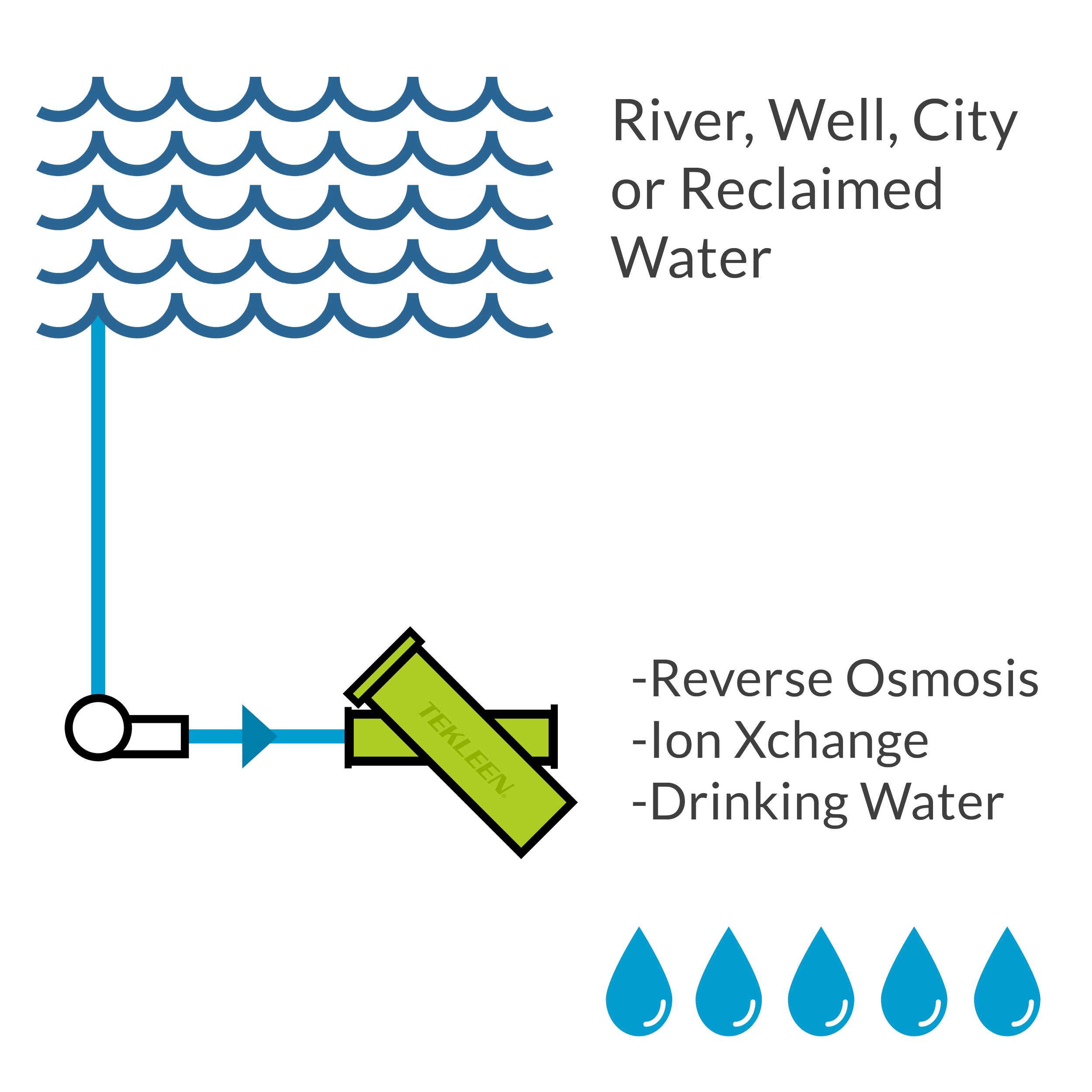

Bottle/can rinsers, pasteurizing tunnels, cooling water, and water re-use and recycling. Process water from the plant's cooling tower is often contaminated with airborne dust, debris, cardboard scraps, labels, and bacteria.

These contaminates circulate through heat exchangers and chillers and significantly reduce the system's cooling ability. In addition, spray nozzles become clogged due to particulates in the system which endanger the quality of the product manufactured. In many cases, chemicals and alternative forms of filtration are used without much luck. This problem results in unscheduled maintenance shutdowns which often cause considerable production losses. This problem may also originate in the pasteurizing and cooling tunnels. Breakages plug the spray nozzles, spot the cans, and create a maintenance nightmare. Also, plant water supply from the municipality or from wells is often contaminated with dirt that causes unscheduled shutdowns for cleaning, costing many plant hours.

Tekleen self-cleaning water filters provide the ultimate solution where dirty water is a problem. The filters operate on line pressure alone. Self-cleaning is triggered by a pressure differential and is accomplished in seconds without interrupting the flow. The filters are compact in size and designed to meet a wide variety of food processing applications. Tekleen filters are available in SST (316L) construction at carbon steel prices.

Case Studies

Get Your Water Free of Debris

Cool, clear water is the life force in manufacturing operations. It cools, cleans, and can be counted on to run pure and steady -- unless it becomes ...

Water Filter Defies Acid Rain

When processing up to 500 jars a minute of jams, preserves and other products, the last thing maintenance needs to worry about is the process water of ...